Add to Cart

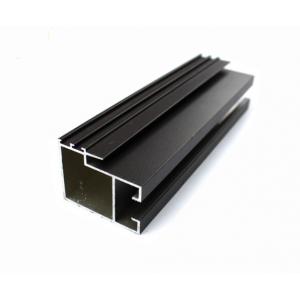

Sliding Windows Aluminum Profile Extrusion Profiles

Detailed Product Description

| Product Name: | Sliding Windows Aluminum Profile Extrusion Profiles | Alloy: | 6061,6063 |

Material : | Aluminium Alloy | Surface Treatment: | Anodized and depend on customer’s demand |

| Shape : | Square, Round, Flat, Oval, and according to customer's drawing. | Temper: | T3-T8 |

Chemical composition

| Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti |

| 6063 | 0.2~0.6 | 0.45~0.90 | <0.35 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

| 6061 | 0.4~0.8 | 0.80~1.2 | <0.70 | 0.15~0.4 | <0.15 | <0.25 | 0.04~0.35 | <0.15 |

Equipment

| Production lines | 22 |

| Anodizing and electrophoresis | 4 |

| Powder Coating | 2 |

| Wood Grain | 4 |

| Painting | 1 |

| Polishing | 1 |

| Brushing | 1 |

| Supply ability | 6000Tons per month |

Certificate

1: Guangdong famous brand

2: The ISO9001 quality management system certification

3: ISO14001 environmental management system certification

4: OHSMS18001 occupational health and safety management system certification,etc.

Packaging & Shipping

| Packaging Details: | 1. Protective film for each piece, then each bundle in Kraft paper 2. According to client's requirement, such as wooden box, iron pallet, etc. |

| Delivery Detail: | Within 15-25 working days after received deposit and and moulds are passed. |

5056: Magnesium alloy and cable sheath rivets, zippers, nails, etc. Aluminium coated wire is widely used in the processing of agricultural insect traps and other occasions where corrosion resistance is required

5083: For situations requiring high corrosion resistance, good weldability and moderate strength, such as ships, automobile and aircraft plate welds; Strict fire protection pressure vessel, cooling device, TV tower, drilling equipment, transportation equipment, missile components, armor, etc

5086: It is applied to the high corrosion resistance, good weldability and medium strength, such as ship, automobile, airplane, low-temperature equipment, television tower, drilling equipment, transportation equipment, missile component and the deck and so on

5154: Welding structure, storage tank, pressure vessel, ship structure and Marine facilities, transportation tank

5182: Thin plate is used to process the lid of the cans, the car body plate, the steering wheel, the reinforcement, the bracket and other parts

5252: Used for making decorative components with high strength, such as cars, etc. After anodizing, the oxide film is bright and transparent

The variety, state and typical use of aluminum alloy

4 series aluminum alloy based on silicon as the main alloying element of aluminium alloy, its most alloys are not reinforced aluminum alloy heat treatment, only including Cu, and Ni alloy, Mg and learned some after welding heat treatment strengthening alloy elements, can only through strengthening heat treatment. Department alloys due to their high silicon content, low melting point, good melt flow, easy feeding, brittleness, and not of the final product so adding material mainly used in the manufacture of aluminum alloy welding, such as soldering plate, wire electrode and candle. In addition, due to some of the piston and heat resistant parts. The alloys containing about 5% of silicon are black and gray after anodizing, so they are suitable for building materials and decorative parts. Current production 4 series aluminum alloy number: 4032