Add to Cart

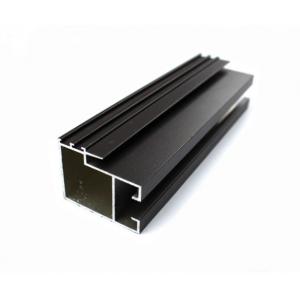

6063 6060 6005 6005A T3 - T8 alloy aluminum window profiles

Specifications

Windows Aluminum Profile

Natural oxidation

ISO:9001&14001

OEM available

2500T Extrusion Equipment

| Product Specification | |

| Description | 6063 6060 6005 6005A T3 - T8 alloy aluminum window profiles |

| Implements National Standard | GB/T6892-2008 |

| Material Thickness(t) | t=1.0 / 1.1 / 1.2 / 1.4 determine by design |

| Adhesion | Grade 0 |

| Material | Aluminum Alloy 6063, 6060. 6005, 6005A, etc |

| Annealing Treatment | F, T1, T4, T5, T6, T61, T64, etc |

| Color | Silver, white, black, wood grain, green, or as request |

| The Largest Extrusion Machine | 2500T Extrusion Equipment |

| Thickness of Powder | 0 |

| Length | Normal length = 3 m, 2m, 1.5m, 1m |

| Package | 1. Pearl cotton foam for each profile; 2. Wrap with shrink film exterior; 3. Packed according to customer request. |

| Advantages/Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

Chemical composition

| Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti |

| 6063 | 0.2~0.6 | 0.45~0.90 | <0.35 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

| 6061 | 0.4~0.8 | 0.80~1.2 | <0.70 | 0.15~0.4 | <0.15 | <0.25 | 0.04~0.35 | <0.15 |

Equipment

| Production lines | 22 |

| Anodizing and electrophoresis | 4 |

| Powder Coating | 2 |

| Wood Grain | 4 |

| Painting | 1 |

| Polishing | 1 |

| Brushing | 1 |

| Supply ability | 6000Tons per month |

Certificate

1: Guangdong famous brand

2: The ISO9001 quality management system certification

3: ISO14001 environmental management system certification

4: OHSMS18001 occupational health and safety management system certification,etc.

Typical use of aluminum alloy

2024: Aircraft structure, rivets, missile components, truck wheels, propeller elements and other structural components

2036: Car body sheet metal parts

2048: Aerospace structural parts and weapon structure parts

2124: Aviation spacecraft structure

2218: Aircraft engine and diesel engine piston, aircraft engine cylinder head, jet engine impeller and compressor ring

2219: Space rocket welding oxidant tank, supersonic aircraft skin and structural parts, working temperature of -270 ~ 300 degrees Celsius. Good weldability, high fracture toughness and high resistance to stress corrosion cracking capacity 2319 welding rod and filler solder

2618: Die forging and free forgings. Piston and aero-engine parts

The variety, state and typical use of aluminium alloy

The 6-series aluminum alloy is the main alloy element of magnesium and silicon, and the aluminum alloy is strengthened by Mg2Si. The alloy has the advantages of moderate strength, high corrosion resistance, non-stress corrosion cracking tendency, good welding performance, constant corrosion property of welding zone, good forming property and good process performance. When the alloy contains copper, the alloy has good strength close to the two aluminum alloy, the process performance is better than the two aluminum alloy, but the corrosion resistance is poor, and the alloy has good forging properties. 6 series alloy alloy is the most widely used in the 6061 and 6063, they have the best comprehensive performance, the main products of extrusion profile, is the best extruded alloy, the alloy is widely used as building material Current production 6 series aluminum alloy card no. : 6005 6060 6063 6082 6262 6463 6 how a02