Add to Cart

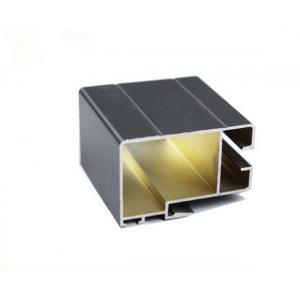

aluminum processing for windows or door aluminum frame building

Specifiaction:

| Product Specification | |

| Description | aluminum processing for windows or door aluminum frame building |

| Material Thickness(t) | t=1.0 / 1.2 / 1.4 |

| Material | Aluminum Alloy 6063, 6061 |

| Annealing Treatment | T5,T6 |

| Color | Green, Grey, Black, White, (RAL series)etc. |

| Surface Treatment | Mill finish, anodized, powder coated, electrophoresis, sand balsting etc.and depend on customer’s demand. |

| Shape | Square, Round, Flat, Oval, and according to customer's drawing. |

| Length | Normal length=6 m |

| Usage | Building, Production Line, Decoration, Industrial, Transportation, Door and window, etc. |

| Package | 1. Pearl cotton foam for each profile; |

| Advantages/Features | Providing colorful products with various mechanical |

Aluminum windows and doors Profiles:

1. High hardness, hard aluminum series.

2. Fair corrosion resistance. Heat treatable

3. Good workability and Good appearance

4. High quality and reasonable price.

5. China's leading manufacturer with more than 20 years experienced

We have the professional engineers team, who research and develop the new product, also we can produce the new product according to customers' idea. OEM & ODM is welcome!

FAQ:

| 1. Q: what’s your MOQ ? |

| R: 3 metric ton for powder and wood. |

| 2. Q: What’s your payment term? |

| R: 30%deposit,70%against the B/L copy or L/C at sight |

| 3. Q: Can you provide samples? |

| R: Yes, we can send you samples according to you needs. |

| 4. Q: Can you do OEM, how about the mould cost? |

| R: OEM is welcomed. The mould cost varies from USD200 to USD500 per set, we don’t charge any fee if your order qty is more than 5 tons (10 tons for curtain wall and industry profiles) |

| 5. Q: Do the price of all the colors are the same with the same surface treatment? |

| R: Not yet, for powder coating ,the bright-colored will cost higher than white or gray; |

| For Anodizing, colorful will higher than silver, black higher than colorful. |

Aluminum alloy for general machine and packing containers

Relationship of optical precision machine

(1) Camera body 5052, 5056, 6262 pipe, rod

(2) Camera Camera parts 1100 and 5N01

(3) component class 2011, 5056, 6262 rods

(4) keyboard 1050 and 1100

(5) gear, floor 2014, 2017, 5083

Fiber relationship

(1) Belt frame 6063, 7003

(2) the textile machine is constructed in 2014, 7075, 01, 7003, and rods

(3) spinning for 2017, 2024, 7075

Chemical composition

| Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti |

| 6063 | 0.2~0.6 | 0.45~0.90 | <0.35 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

| 6061 | 0.4~0.8 | 0.80~1.2 | <0.70 | 0.15~0.4 | <0.15 | <0.25 | 0.04~0.35 | <0.15 |

Equipment

| Production lines | 22 |

| Anodizing and electrophoresis | 4 |

| Powder Coating | 2 |

| Wood Grain | 4 |

| Painting | 1 |

| Polishing | 1 |

| Brushing | 1 |

| Supply ability | 6000Tons per month |